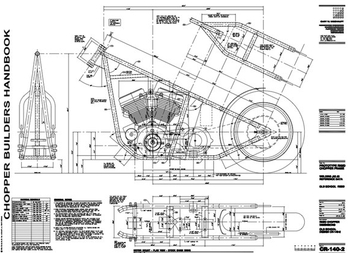

There are four leveling adjustments on the feet extending out from the parallel rails. Notice the adjustments that are available for the steering neck, rear axle plates and seat post. To the above right is an example of a builders Jig. If you tackle this job yourself, remember, it will always remain a "work-in-progress" as you fabricate your frame. To build a jig yourself, and I mean all the machining and other work yourself, you will have to invest anywhere from $200 to $700 in materials alone. In either case, the cost would be prohibitive to the small shop or the individual builder.

The jig would have to be tailored to the bike design, or be infinitely variable. The beginning price could be anywhere from $5,000 upwards for an adjustable jig. Commercial chopper frame jigs are very expensive.

0 kommentar(er)

0 kommentar(er)